Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Construction takeoffs are an essential part of any building project. They help estimate the materials, costs, and time required to complete a construction job. However, many challenges can arise during the takeoff process, leading to costly mistakes and project delays. By understanding these challenges and knowing how to overcome them, you can improve the accuracy of your estimates and enhance your construction workflow.

A construction takeoff is the process of calculating the quantities of materials needed for a construction project. This step is crucial because accurate takeoffs ensure that the right amount of materials is ordered, preventing shortages or excess purchases.

Professionals use different methods for takeoffs, such as manual calculations, digital software, or a combination of both. Many construction companies rely on professional quantity takeoff services to improve accuracy and efficiency.

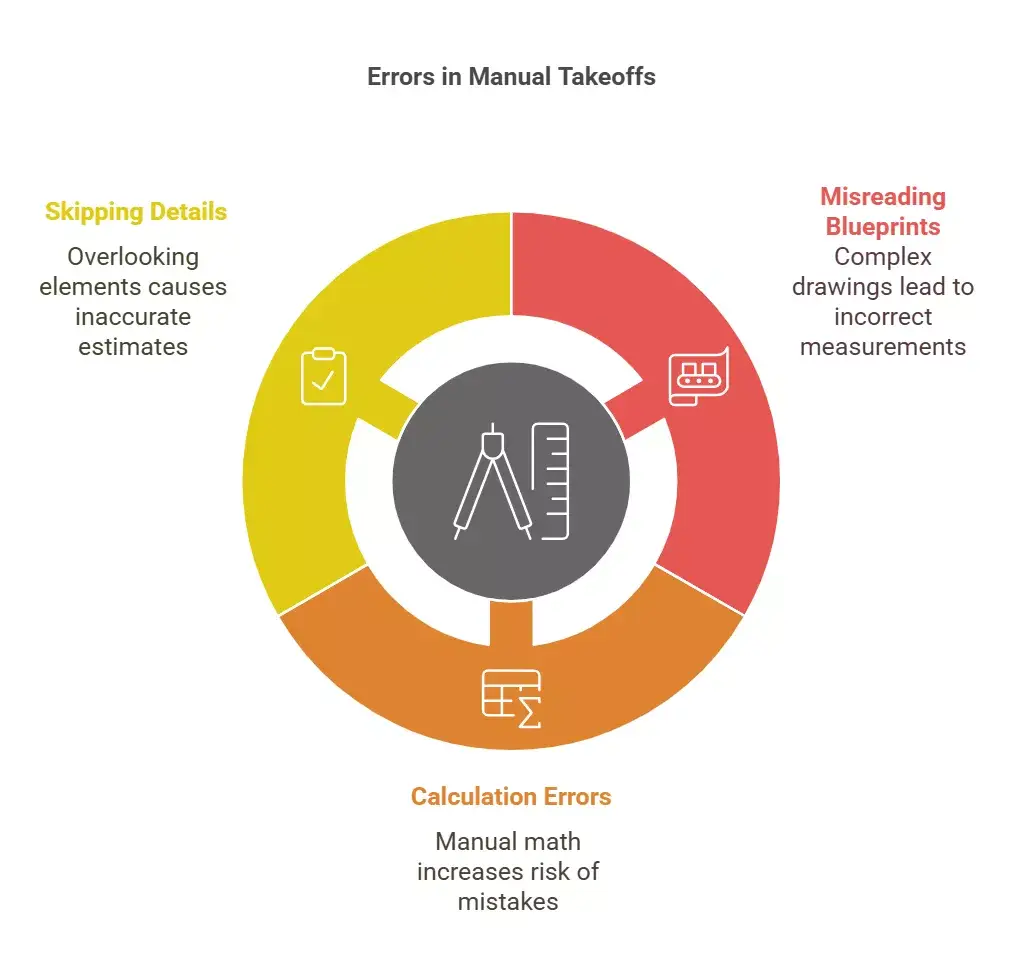

Manual takeoffs require a high level of attention to detail. Even a small miscalculation can lead to major cost overruns or delays. Some common mistakes include:

Accurate measurements are essential for successful construction projects. Errors in measuring materials can lead to underestimations or overestimations, causing:

Construction plans often change due to design modifications, client requests, or site conditions. If takeoffs are based on outdated blueprints, errors can occur.

Large and complex projects require detailed takeoffs for multiple materials, including:

Managing such vast amounts of data can be overwhelming. Utilizing a construction estimate service can help simplify the process and ensure accurate calculations.

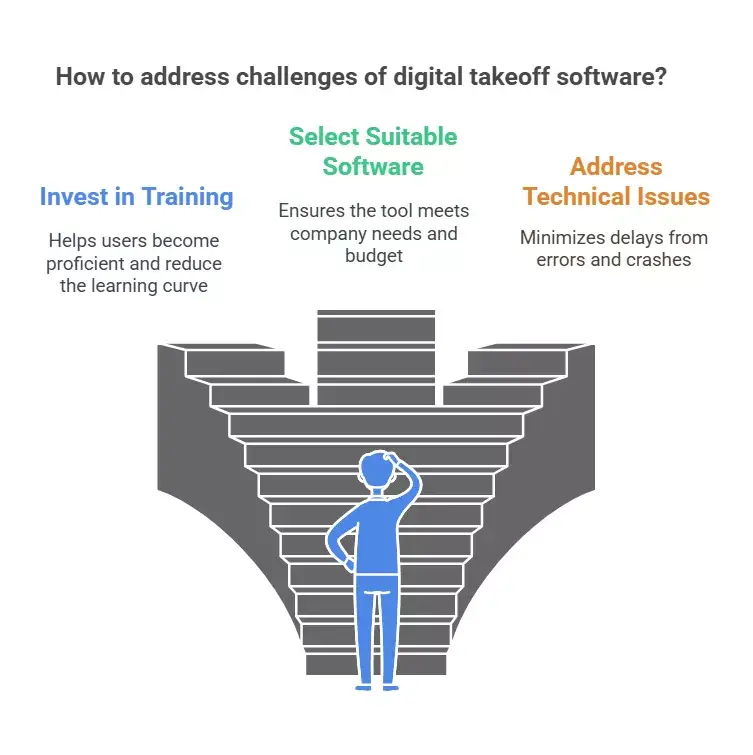

Many construction companies use digital takeoff software to improve accuracy, but these tools come with their own challenges:

To overcome these challenges, invest in training and select software that suits your company’s needs.

Takeoffs involve multiple teams, including estimators, project managers, and suppliers. Poor communication can lead to:

Implementing a centralized system allows all teams to access and update information in real-time, helping to prevent these issues.

Material costs fluctuate due to market conditions, transportation fees, and supply chain issues. Relying on outdated pricing data can lead to inaccurate estimates. To manage this:

Labor costs vary based on skill level, location, and project complexity. Underestimating labor expenses can lead to budget issues. To improve labor cost accuracy:

Investing in takeoff software can help automate calculations, reduce errors, and save time. Popular tools include:

Hiring experts for construction estimate services ensures precise takeoffs. Professional estimators have experience handling complex calculations and use advanced tools to improve accuracy.

Ensure that takeoffs are based on the latest project plans. Hold meetings with architects, engineers, and project managers to review any changes before finalizing takeoff calculations.

Encourage collaboration between estimators, project managers, and suppliers by:

Keep track of material and labor cost trends by:

Before finalizing takeoff data, review all calculations to minimize errors. Have another team member verify measurements and material quantities.

Construction takeoffs play a critical role in the success of a project. While challenges like manual errors, outdated blueprints, and fluctuating costs can make the process difficult, implementing the right strategies can improve accuracy. Using digital tools, working with professional estimators, and maintaining clear communication can help streamline the takeoff process.

PHONE NO:

+1 469 555 3890

MAIL ADDRESS:

Info@axisestimate.com

0 Comments