Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

In my line of work, thermal moisture protection can make or break a structure’s durability, energy efficiency, and longevity. Personally estimating moisture protection and insulation has taught me one thing: getting the estimating process right is a matter of critical importance. If you do not achieve accurate estimates, you risk going over budget, incurring excessive delays, and improperly securing structures in ways that render them susceptible to moisture damage in the future.

This guide is intended to provide you with the pointer of thermal moisture protection estimating—explaining its importance, along with best practices and challenges faced when attempting to achieve the described protection. It is my intention to provide you with the experiences and lessons I have acquired to help aid in navigating this essential element of construction.

Thermal Moisture Protection entails the management of construction moisture and heat within a building. It guarantees that thermal and moisture insulation is maintained without allowing water or moisture to escape through walls, floors, and ceilings. Protecting thermal moisture issues during construction has helped me practice improving energy efficiency while protecting structural integrity over the years, leading to healthier living conditions for the residents.

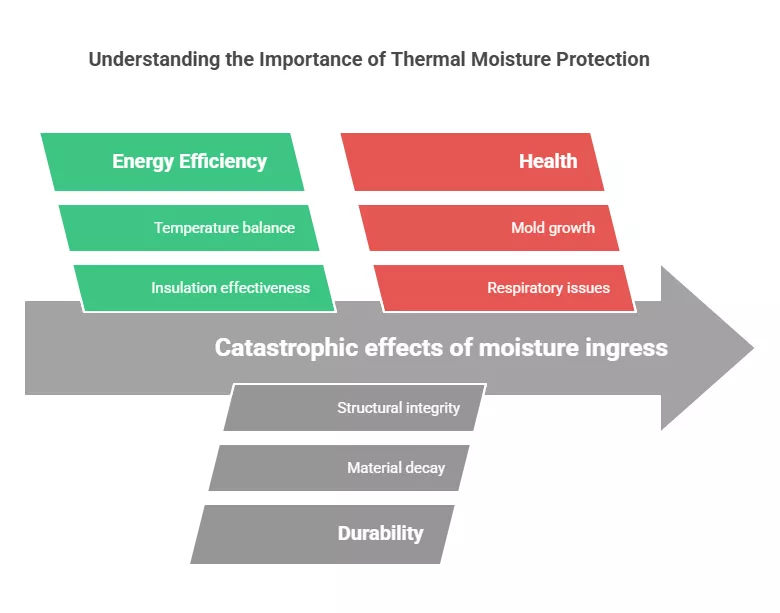

As remarked above, the protection of thermal moisture is vital for the elimination of water related incidents which gives rise to mold, wood decay, and decomposition of insulation materials, and mostly serves for energy efficiency purposes.

Having worked on different projects, I have witnessed the problems caused by moisture ingress and how it can lead to further issues. Moisture is truly one of the more catastrophic elements and without skillful management leads greatness towards hardships. Below are few of the reasons why moisture control is an important aspect to focus on:

While estimating construction costs involving soft, thermal, thermal monolithic, and thermal shell moisture protection, there are several considerations that may influence your selection of material, as well as the overall cost. Based on my experiences, here is what you ought to know:

All buildings are distinct, and so are the thermal moisture protective systems tailored to their needs. Take for instance the project I worked on, a multi-story office building. The roof design posed a challenge because of the acute slope, which created water accumulation issues. As opposed to, a simple single story house probably receives less attention for barriers, but still, needs good insulation and vapor retarder.

High level structure complexity comes with defined scope of materials needed and work effort for installation. In more complex, multi-detailed structures, estimating projects becomes more intricate due to the higher amounts of protection that often needs to be included.

From coastally warm and damp to dry and cold, I’ve worked in all kinds of climates. In moist locations like Florida, moisture barriers are vital to prevent mold and mildew growth. In colder areas, however, insulation mostly does the work alongside vapor barriers to keep condensation out of walls. To evaluate overheating strategies properly, one must know the setting as well as the materials used in construction.

The thermal moisture protection materials you choose impact your estimate quite a lot. For instance, in some of the projects I’ve worked on, fiberglass insulation was thermally resistant and affordable and therefore provided the best value. In some of the other projects, especially those dealing with moisture concerns, I have used spray foam insulation with a vapor barrier, which, although more expensive, is a better overall solution.

Some materials include:

The cost and durability of these materials can vary, so it’s essential to assess what is best suited for each specific project.

Moisture control is one of many aspects that needs to be taken into consideration by specific building codes per area. There are instances where estimates required changes due to local building codes needing extra moisture barriers or insulation added on or around certain areas. An example of this would be that New York City verges on more extreme as far as considering insulation and moisture control compared to places with lesser population density.

It is critical that one monitors ongoing changes in local building codes and ensure relative estimates do not exceed set boundaries, as that would inhibit timelines for work needed to be performed later.

Based on years of working on different projects, here are some best practices I’ve found invaluable for ensuring accurate thermal moisture protection estimates:

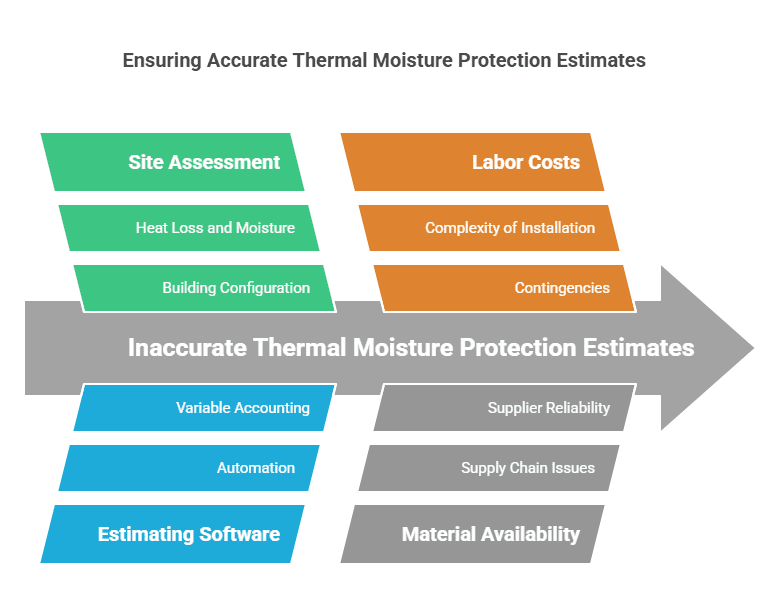

An onsite inspection is highly recommended prior to making any estimates. This is of utmost critical importance for a new construction, and even more so for a renovation. Identifying the particular building configuration is a major factor. I use thermal cameras which identify places where heat loss occurs and where moisture build up is prevalent.

In today’s fast-paced world, I don’t rely solely on manual calculations. Instead, I use estimating software like ProEst or Buildertrend. These tools help me create accurate estimates faster by automating calculations and accounting for variables like material costs and labor hours. These systems are especially useful when handling large-scale commercial projects with intricate thermal moisture protection needs.

Labor costs can vary greatly depending on the complexity of the project. In my experience, installing thermal moisture protection in hard-to-reach areas, like attics or the exterior of high-rise buildings, will take more time and, thus, cost more in labor. I always build in contingencies for labor to account for unforeseen challenges like bad weather or labor shortages.

Halted supplies may increase costs while pushing deadlines further out. Personally, I have faced several challenges where international logistics bottlenecks affected my material calculations. The possibility of shift value of the specific materials being ordered and out of stock has to be taken into account. Also, I make sure that the suppliers I use have the necessary materials set aside or ready before I place an order and confirm the calculated estimate.

Over the years, I’ve seen the estimating process evolve with the introduction of new technologies:

I’ve encountered a few challenges in my years of estimating thermal moisture protection, and here are the most common ones:

The weather affects installations plans more than most think. For instance, rainfall can delay the scheduling of protective coating applications, and that will inevitably affect timelines. In any planning, extra time needs to be scheduled for adjustments in estimates and factors that pertain to the ever-changing weather.

Flexibility within design estimating processes is essential due to potential changes on large scale projects. In the estimating phase, I recall a client altering the entire building design’s sketch and needing the thermal moisture protection systems recounted due to the new design revisions. Such changes increase costs and complexity.

Estimating thermal moisture protection with precision is crucial for energy-efficiency in buildings. After working on a number of projects, I believe moisture control systems and energy-efficient systems work together for the longevity of the structure.

By following best estimating practices: structure, environment, and materials including design, perform in parallel to achieve the best result. Implement technologies that make the job easier but keep an open mind towards changes in scope.

Remain up to date through literature, adapt to changes throughout the project, and focus on meeting unique deadlines and requirements if you are involved in a thermal moisture protection design project.

0 Comments