Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

An accurate material takeoff is arguably one of the most essential in any construction project. In my many years of project managing, I’ve seen that a single inaccurate takeoff has the potential of throwing entire schedules into chaos both in terms of timing and spending. This is especially true for thermal moisture protection (TMP). In this article, I put down some lessons that could enable you to do accurate material takeoffs for TMP projects, thus making your bids more dependable.

Before we get into the specifics of material takeoffs, let’s quickly break down what thermal moisture protection (TMP) is. TMP is all about using materials that control the movement of heat and moisture through the building. I’ve seen first-hand how crucial this is to ensure that a building stays energy-efficient and protected from water or moisture damage.

Here’s what TMP usually involves:

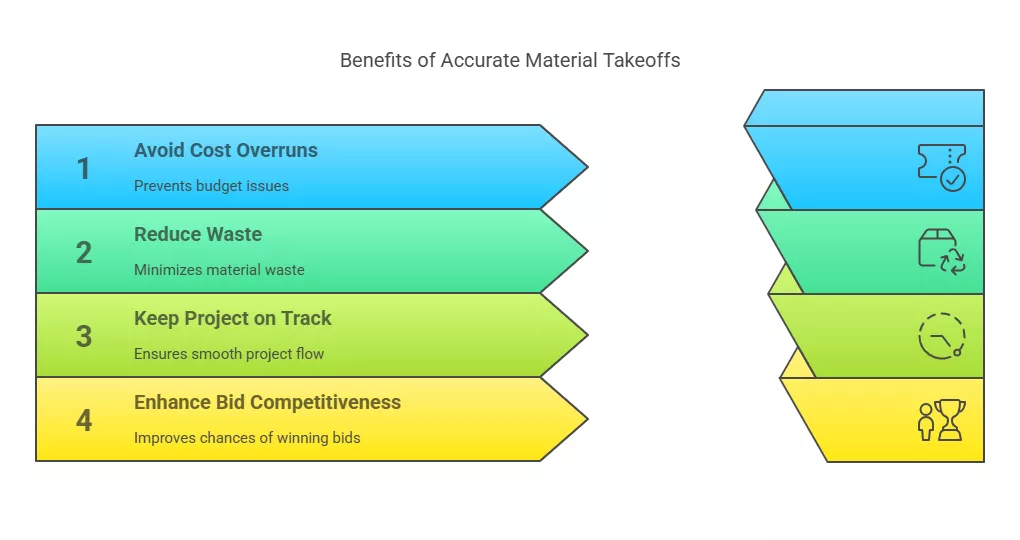

A material takeoff is a detailed list of all the materials you need for a project and how much of each you’ll need. I’ve learned that having a precise takeoff for a TMP project is crucial because:

Having worked on a few TMP projects myself, I can tell you that doing an accurate material takeoff is not as hard as it seems. Here are some tips that have helped me along the way:

A fresh undertaking requires attention to the architectural schematics alongside the specific project details, which I always complete in the very first step of a new project. Each project might have unique TMP needs, which makes this step fundamental.

In one of my earlier undertakings, I noticed the insulation specified was not calibrated in accordance with the prevailing climate. With the help of these specifications, I was able to modify the takeoff so that the building was energy efficient.

Precision is crucial when conducting material takeoffs. I strive to capture all dimensions of walls, ceilings, and floors accurately, paying attention to horizontal and vertical measurements which might be negligible to others. In the case of insulation, I estimate the additional material required to account for overlaps, wasteful cuts, seams, etc.

I was hired to assist with a large building and was shocked to discover the shortfalls about how improperly waste was accounted. That mistake cost us a fortune, taught me a lesson, and made me careful with these calculations for the future.

It’s about more than just the number of projects undertaken, as the overall result matters too. The R value, which defines the level of insulation’s thermal resistance, determining the insulation’s moisture resistance and material strength all are highly significant. Such metrics allow me to make informed decisions that help me meet my requirements in every project I handle.

Considering the atmosphere where a project will be undertaken is crucial, as is knowing the expected temperatures. For example, I know that for humid regions, having a strong vapor barrier is non-negotiable. Making decisions based on prior experiences allows me to avoid issues that stem from selecting the wrong materials for a project.

As far as construction goes, every location has its building codes and my area of focus pays attention to them very closely. Thermo-regulated buildings have certain aspects of unattainable standards, such as conserving energy or achieving a specified R-value for insulation. The local climate also governs what materials I select. For instance, I may require thicker insulation in colder climates, while hot and humid areas demand greater attention to moisture control.

At one point in time, I was working on a project in really cold climatic conditions; I had to literally change the building template after reviewing the local codes. If I had skipped this step, the insulation would have been considered subpar, and my thermostat would have sent ungodly spike warnings on intrepid pagers for heating issues on the horizon.

When working on TMP projects, there are often multiple layers involved. Insulation, vapor barriers, and air barriers all play a role in a building’s energy efficiency and moisture control. I always double-check the thickness and area coverage for each layer to ensure accuracy.

For example, I once worked on a building where the insulation needed to be combined with both a vapor barrier and an air barrier. Getting the takeoff for each layer right helped avoid delays when it came time to install these materials.

I can’t recommend takeoff software enough. I use tools like Bluebeam and PlanSwift to measure areas directly from digital drawings. These tools are a game-changer because they help save time and make the material takeoff process much more accurate. By using this software, I can easily calculate quantities and even factor in material waste.

In one of my projects, using software to create a material takeoff saved me hours compared to manually measuring each area. It also helped me catch mistakes that I might have missed otherwise.

Even with experience, I’ve made a few mistakes along the way. Here are some that I’ve learned from:

Working together is essential for ensuring accuracy. I never fail to crosscheck the material takeoff in conjunction with my team which includes contractors and suppliers. In my opinion, a fast walkthrough of the work will resolve any problems almost immediately in an efficient manner, which will make time management easier in the long run.

Additionally, going to the site prior to beginning the work helps me wrap my mind around the layout of the work as well as any special factors or conditions that could affect the framework.

Getting your material takeoff right is crucial for thermal moisture protection (TMP) projects. By following these tips and learning from past experiences, I’ve been able to make more accurate bids, avoid costly mistakes, and complete projects on time. The key is careful planning, precise measurements, and collaboration with your team.

Whether you’re new to TMP projects or have been in the field for years, these tips can help you improve your material takeoffs and ensure your bids are as accurate as possible. I hope you find these insights helpful!

0 Comments