Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

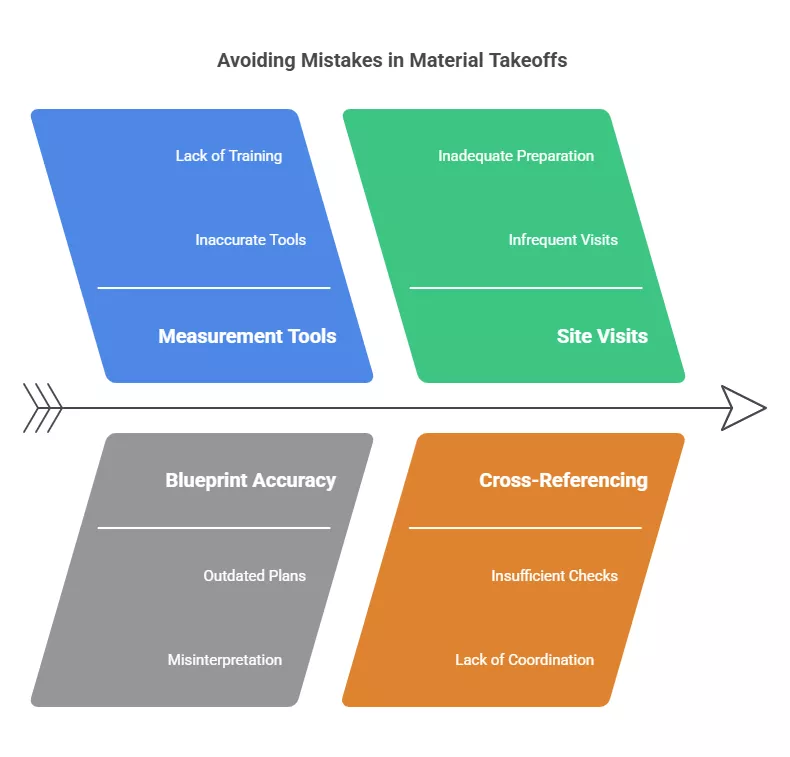

Accurately estimating the needed materials for construction comes as a daunting task for an estimator or project manager. The extent of lasting damages to a project stemming from a materials takeoff error runs dangerously high, and includes, but is not limited to, added costs, wasted time, and delayed deadlines. This definitely sounds familiar to anyone who has experienced the exacerbating consequences associated with either a material shortage or the overflowing surplus of materials delivered to a construction site. My main question is, how would one steer clear from these misconceptions while guaranteeing maximum accuracy throughout the entire estimating process?

This is precisely the direction I’ll be taking with this article; share lessons learned from personal experiences throughout my construction career. Along the way, we will discuss the myriad ways through which material takeoff estimations can go awry. But more critically, we will ensure that material takeoff estimation is approached in a manner that makes certain project remain within scope, are budget-friendly, and are completed on schedule.

Before we discuss common errors, let us first analyze why a material takeoff (MTO) is crucial. In simple terms, a material takeoff refers to calculating the materials required for a construction project. It helps in cost estimation, planning procurement, and ensuring construction workflows seamlessly by allocating the right materials at the appropriate times.

As someone who has been involved with numerous projects ranging from small residential builds to large commercial ones, I have experienced how takeoff inaccuracies can be a project derailleur. These errors, whether an overestimation or underestimation, will affect budgets, timelines, and overall project success. Let us, therefore, discuss the most common errors associated with material takeoffs and how you could avoid them.

When working on-site, I find that one of the most challenging is pertained to omitted or missed measurements. I’m guilty of missing a detail or two when it comes to bulk take-off procedures in the construction project management process. At first glance, this does not appear to be a major challenge, but it can create some quite large problems later.

Solution:

In the initial stages of my professional journey, I neglected to consider waste due to cuts, errors, or intrinsic flaws in the materials. This step was essential; otherwise, I found myself rushing to order additional materials which resulted in self-imposed deadlines. This, in turn, increased my costs. I came to understand that construction materials such as drywall, concrete, and lumber have accompanying waste factors that must be considered during measurements.

Solution:

There was a project in my previous work where the most recent blueprint was not disseminated to the team. We followed an old version and by the time we noticed other changes like expanding the floor plan and adding new rooms, we had already started the ordering phase. This mistake delayed the project completion timelines and increased expenses.

Solution:

Before, I depended a lot on hand draw takeoffs and manual calculations. Even though it can be done with smaller projects, it is highly inefficient for larger projects. I remember some instances where I miscalculated material requirements which led to delays and inconveniences with the contractors and suppliers.

Solution:

Once, I underestimated the materials needed for a project due to site conditions. A construction site may seem straightforward on paper, but factors like uneven ground, steep slopes, and hidden structural elements can change the material requirements.

Solution:

I once had a major mishap when ordering materials for a project that used both imperial and metric units. The conversion errors led to discrepancies in quantities and, unfortunately, unnecessary delays and frustration.

Solution:

In my previous projects, the interplay (or lack thereof) between the estimator and suppliers more often than not ended in miscommunication which resulted in delays. This is most noticeable when it comes to the provided list of materials and their description. Inaccurate descriptions can lead to the provided materials being different than what is actually needed for the project, which in turn, impacts the entire project timeline.

Solution:

Here are some best practices I’ve implemented that have greatly improved my material takeoff accuracy over the years:

Although material takeoffs appear to be a simple task, the issues noted here every so often result in expensive outcomes. From my experience, the most accurate measurements are taken with the most recent plans, up to date tools, and waste allowances, modern tools, and accurate plans. By applying the solutions outlined here, you will reduce inaccuracies, control expenses, and ensure an efficient project schedule. Achieving accuracy in material takeoffs translates to easier projects, better respect from clients, and reduced stress for all parties concerned.

Software like ProEst, Buildertrend, and PlanSwift can automate your material takeoff process, ensuring accuracy and efficiency.

Always account for waste and double-check all measurements before ordering materials. Using software tools can help automate this process for you.

Update your takeoff whenever there are significant design changes or revisions to the plans. Regularly check for new updates to ensure accuracy.

1 Comment

Kathy16

Good