Estimating the amount of drywall needed correctly matters with regards to constructing a home office, theater, studio, or undertaking other soundproofing projects. The value of thorough planning can’t be overstated as planners, including myself, who have undertaken numerous soundproofing projects understand that accuracy, either overestimating or underestimating the amount of materials, is primary for efficiency.

For these reasons, I wish to detail the step-by-step process of estimating drywall for soundproof drywall projects while also detailing the important lessons I have learned throughout actual projects, accompanied with tips for avoiding the more rudimentary blunders.

What is Soundproofing, and Why Does It Matter?

Soundproofing refers to preventing sound from entering or leaving a space and is something we all need in quiet-importance spaces such as home theaters, recording studios, or offices. But, many people don’t know that drywall greatly assists in this process.

The issue is: if you want to achieve soundproof drywall, there is more than adding a layer or two of standard drywall—there are the proper materials, methods, and estimations needed to get the work done right.

Types of Drywall for Soundproofing

Not all drywall is created equal, especially when it comes to soundproofing. I’ve worked with a variety of drywall types, and each one offers different benefits. Let me explain the main ones:

- Standard Drywall vs. Soundproof Drywall

Standard drywall (the kind most contractors use) isn’t great for soundproofing. It’s thin and lets sound pass through easily. On the other hand, soundproof drywall is much thicker and denser. It’s specifically designed to block sound. Using thicker drywall layers will help you better reduce noise.

- Acoustic Drywall (QuietRock and Similar)

When soundproofing is a priority, I usually recommend acoustic drywall like QuietRock. It’s designed to stop sound from passing through walls and ceilings effectively. Though it’s pricier than regular drywall, it’s one of the most effective solutions when you’re aiming for a quiet environment.

- Mass-Loaded Vinyl (MLV) and Resilient Channels

In my experience, combining drywall with other materials like Mass-Loaded Vinyl (MLV) and resilient channels can make a significant difference. These materials absorb and isolate sound even more. Resilient channels are installed between the drywall and the wall studs, which helps decouple the drywall and reduces sound transmission.

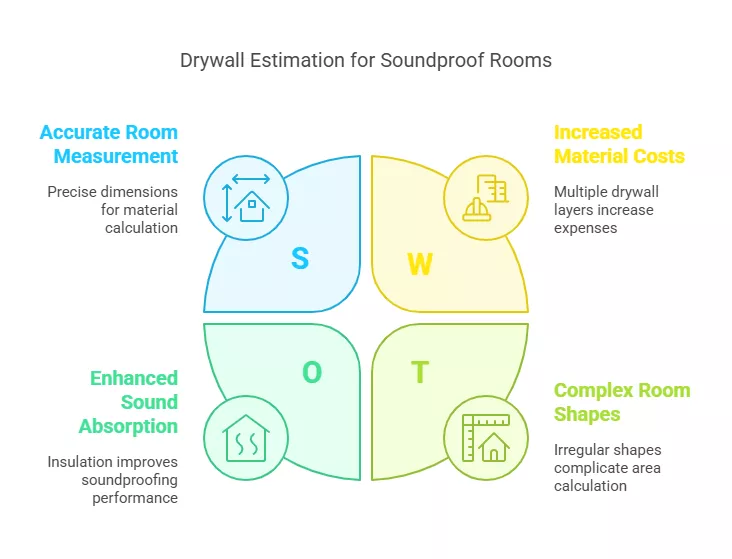

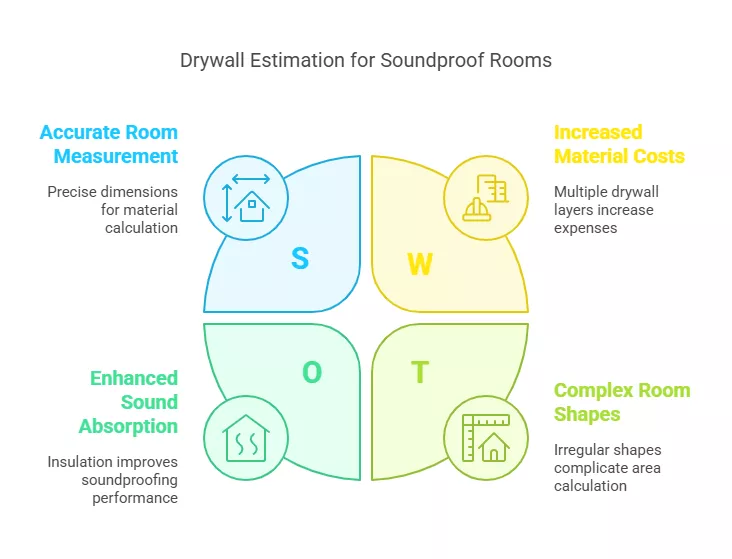

Key Considerations for Estimating Drywall for Soundproof Rooms

When you start estimating drywall for soundproofing, there are a few key factors to keep in mind. Here’s what I look at every time:

- Room Size and Shape

The first step is to measure the room accurately. The larger the room, the more drywall you’ll need. It’s also important to consider the room’s shape. Irregularly shaped rooms can be trickier, and you’ll need to calculate the area of each wall to determine how much material you’ll need.

- Wall Thickness and Layers

In soundproof rooms, thicker walls are essential. This might mean adding more layers of drywall, which increases both material and labor costs. I’ve had to use multiple layers in some of my projects, especially when the client needs top-notch soundproofing. Keep in mind that the thickness of the drywall you choose will directly affect the final cost.

- Insulation

Insulation is an important part of soundproofing. It absorbs sound and helps prevent it from traveling through the walls. I’ve found that using fiberglass insulation or foam insulation between drywall layers helps a lot with soundproofing. Make sure to factor in the amount of insulation you’ll need.

How to Estimate Material Costs for Soundproof Drywall

I’ve seen contractors make mistakes by not factoring in all the materials needed for a soundproof room. Here’s how I estimate the materials:

- Calculate the Number of Drywall Sheets

The first step is to measure the total surface area of the walls. Standard drywall sheets are typically 4 feet by 8 feet. So, if you know the size of the room, you can easily calculate how many sheets you’ll need.

For example, if you’re working with a room that is 12 feet by 12 feet with 8-foot walls, here’s the calculation:

(12 feet x 8 feet x 4 walls) = 384 square feet.

Divide that by 32 (the area of one standard sheet of drywall), and you get around 12 sheets of drywall. For soundproof drywall, you’ll need to adjust this estimate depending on the thickness and type of material you choose.

- Consider Acoustic Materials

Soundproof drywall like QuietRock is more expensive than regular drywall. Depending on the room size and soundproofing needs, the cost can add up quickly. I’ve worked on projects where the cost of drywall alone took up a significant portion of the budget. Don’t forget to add any additional materials like acoustic sealants or MLV for extra soundproofing.

- Additional Materials

Other items to include in your estimate are screws, adhesive, and any resilient channels. These materials help secure the drywall and reduce sound transmission. In my experience, these extra components can sometimes be overlooked, but they are necessary for achieving optimal soundproofing.

Labor Costs and Time Estimates for Installing Soundproof Drywall

Installing soundproof drywall takes longer than regular drywall because it’s heavier and may require more layers. I’ve worked on several soundproofing jobs, and here’s what I’ve learned:

- Time to Install

The installation time for soundproof drywall depends on the room size and the number of layers you’re adding. Expect the process to take longer than typical drywall installation. For example, a simple 12×12 room may take 8-10 hours to install if you’re adding multiple layers of soundproof drywall.

- Labor Costs

The labor cost will vary depending on where you’re located, but it’s usually more expensive than regular drywall installation due to the added complexity. For example, installing resilient channels and acoustic materials requires more skill and time, so the labor costs tend to be higher.

How to Calculate the Total Cost for a Soundproof Room

Let’s break down a simple cost estimate for a 12×12 room:

- Material Costs

For soundproof drywall, let’s assume you need 12 sheets, and each sheet costs around $50. That brings your material cost to $600. Add in insulation and resilient channels, which may cost around $200.

- Labor Costs

If labor costs $50 per hour and it takes 10 hours to complete the job, the labor cost would be $500.

- Total Estimate

Adding everything together, your total estimate would be around $1,300 for a standard 12×12 soundproof room. Keep in mind that larger rooms or higher-end materials will increase the cost.

Common Mistakes to Avoid When Estimating Soundproofing Projects

Over the years, I’ve seen contractors make a few common mistakes when estimating soundproof rooms:

- Underestimating the Amount of Material Needed

Always double-check your calculations. It’s easy to misjudge the amount of drywall and insulation needed, especially for larger or oddly shaped rooms.

- Ignoring Additional Costs

Don’t forget about the extra costs for sealants, adhesives, and acoustic materials. These small expenses can add up quickly.

- Underestimating Labor

Soundproofing drywall is more labor-intensive than standard drywall installation. Make sure to account for the extra time it takes to install multiple layers and specialty materials.

Conclusion

The estimation of drywall for soundproof rooms can be complicated. However, with the appropriate strategy, you can guarantee that your project remains on schedule and does not exceed the budget. Careful measurement of the room, selection of the appropriate materials, and consideration of both material and labor costs will enable you to provide soundproof rooms that are of the highest quality.

In my observation, the accuracy of your estimates combined with a clear understanding of the soundproofing requirements will impact the project’s success. Remind yourself that every job comes with its own set of requirements and challenges which will require adjusting your estimates accordingly.

0 Comments