Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

As with other industries, construction project planning is somewhat challenging due to the need to estimate material quantity accurately, in this case lumber. Traditional methods oftentimes rely on calculating by hand which is inefficient and riddled with errors. However, at the construction industry lap, lumber takeoff services are heralding a revolution by enabling construction industry players to plan more accurately, faster, and with less money.

After several years in the construction realm, I have seen how technology can change planning and the management of work activities. Today, I will demonstrate how lumber takeoff services can help modernize project planning, minimize waste, and streamline project workflow.

Lumber takeoff services describe the estimating of a construction project’s lumber requirements. With these services, blueprints or designs of a project are fed into some specialized software to obtain them in a more accurate way. Unlike the so called “manual” methods that entail measuring and calculating by hand, digital takeoff services employ CAD and BIM technologies whose automation guarantees accuracy.

In my case as a manager of construction projects, I have witnessed how the use of these tools alleviates the headaches associated with estimating material quantities. Integration of lumber takeoff services ensures construction teams arrive at realistic estimations of how much lumber is required, consequently improving accuracy while reducing risk, delays, and costs.

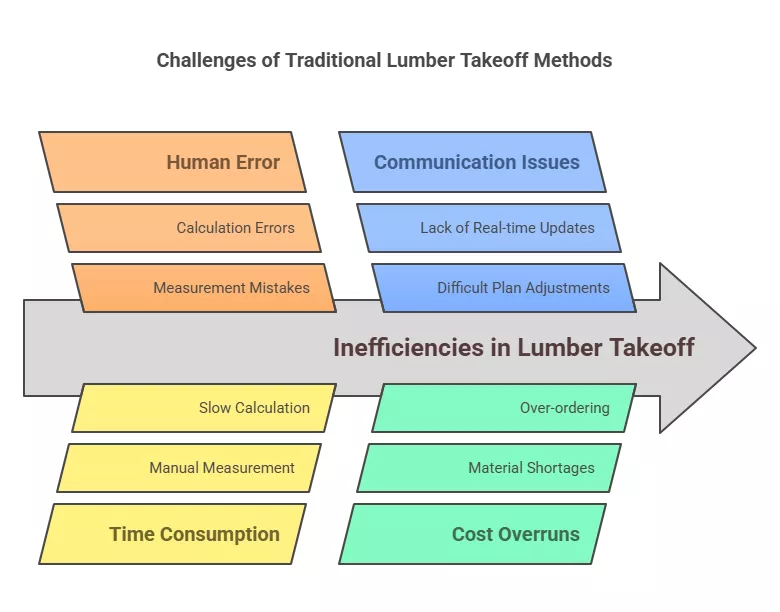

For many years, the lumber takeoff process relied on traditional manual methods, which involved measuring and calculating each piece of wood by hand. These methods were not only time-consuming but also highly susceptible to human error. Small mistakes in measurements or miscalculations could lead to costly issues on-site, such as:

As someone who has worked on numerous construction projects, I’ve seen firsthand how these issues can derail a project. Manual takeoff methods also required a lot of back-and-forth communication between teams and suppliers, making it difficult to get real-time updates or make adjustments when plans changed.

Lumber takeoff services have introduced a more efficient and accurate way to plan construction projects. Here’s how these services can modernize the planning process:

Your company’s reputation can be built or destroyed through the accuracy of technology. As with any industry of tremendous competition, takeoff services are bound by intense accuracy requirements. Land estimating errors translate to budget issues. Investing in technology generates confidence of primary estimators and ensures no automation errors will take place.

Foremost, heightened personalization allows the use of both tangible materials and specifically directed computers for algorithm output. Minimization of physical/labor error occurs when clear specifications disable loose interpretation of the problem, this is solved with pinpoint targeting possible through optimally tailored software.

For software applied logic errors cannot occur, otherwise reputation is obliterated. Unconventional estimating with adjustments for intentional damages such as cuts or shapes exceeds standards, which normalizes waste measurement.

During project over a sheriff’s department building, failure of proper lumber issue fueling public discontent was rebutted by enormous trust by switching to automating estimate process. Without syntactic analysis loopholes are nullified ensuring each clause will be addressed with reliability.

Old school estimating lumber quantities was exceedingly complicated and would often take days to finish. In comparison to rest, modern lumber takeoff services provide for seamless integration with construction teams, automating material estimation processes and providing estimates in less than an hour.

For instance, in one of the recent projects I attended to, our team was able to complete estimation in a matter of hours due to the fact that we utilized a cloud-based lumber takeoff service. Ranging from weeks to several days for rough-quote estimation. Complete inaccuracy due to manual calculations provided entire automation which exceeded our previous expectations and improved workflow. These changes to workflow allowed for an improved initiation of the procurement process and the seamless integration put the project back on schedule.

In my experience, using lumber takeoff services can lead to substantial cost savings by preventing the over-ordering of materials. Accurate estimations mean that only the necessary amount of lumber is ordered, reducing waste and ensuring that the project stays within budget.

Additionally, having precise material quantities allows project managers to negotiate better pricing with suppliers. On one project, the team was able to get bulk discounts on lumber due to the accurate material forecast, which saved us money in the long run.

Project plans are often subject to change due to unforeseen circumstances. In my time on construction sites, I’ve seen how critical it is to stay adaptable when changes are made to the design or scope of the project. Lumber takeoff services allow project managers to make real-time updates to material estimates whenever changes occur. This flexibility means that the team can adjust quickly to design changes or material substitutions without disrupting the overall timeline.

For instance, when the design of one of my projects changed midway through, we were able to update the material quantities in the takeoff software and receive updated cost estimates almost instantly. This saved us valuable time and helped prevent project delays.

Modern lumber takeoff services are often cloud-based, meaning that project teams, contractors, suppliers, and other stakeholders can collaborate in real time. I’ve found that this transparency and ease of communication improve collaboration and reduce misunderstandings. When everyone is working from the same set of accurate data, there’s less room for mistakes and miscommunication.

By sharing real-time updates and material quantities, contractors can make informed decisions about when and how materials should be delivered, ensuring that the project stays on schedule.

Lumber takeoff services rely on cutting-edge technology to streamline the material estimation process. Here’s a brief overview of the main technologies used:

BIM is one of the most widely used technologies in modern lumber takeoff services. It creates a 3D digital model of the entire construction project, allowing teams to visualize how materials will fit into the design. This technology makes it easy to calculate the amount of lumber required and adjust material quantities based on design changes. From my perspective, BIM’s ability to provide an integrated view of the project makes it invaluable in improving the accuracy of lumber estimates.

CAD software allows designers to create detailed drawings of the project, which can then be used to generate material takeoffs. It is a powerful tool for accurately calculating the dimensions of lumber and ensuring that the right materials are ordered. Over the years, I’ve seen how CAD integration with lumber takeoff services enhances precision and speeds up the entire process.

Cloud-based platforms make it possible for project teams to access data remotely and collaborate seamlessly. This technology helps avoid delays caused by miscommunication and enables project managers to make timely decisions. By using cloud-based lumber takeoff services, construction professionals can stay updated on material estimates, delivery schedules, and project timelines in real time.

Artificial intelligence (AI) and machine learning are increasingly being used to optimize lumber takeoff services. These technologies can analyze past project data and make more accurate predictions about material requirements. This innovative approach has significantly improved the accuracy of material estimations, and in my experience, it’s helping construction teams complete projects more efficiently.

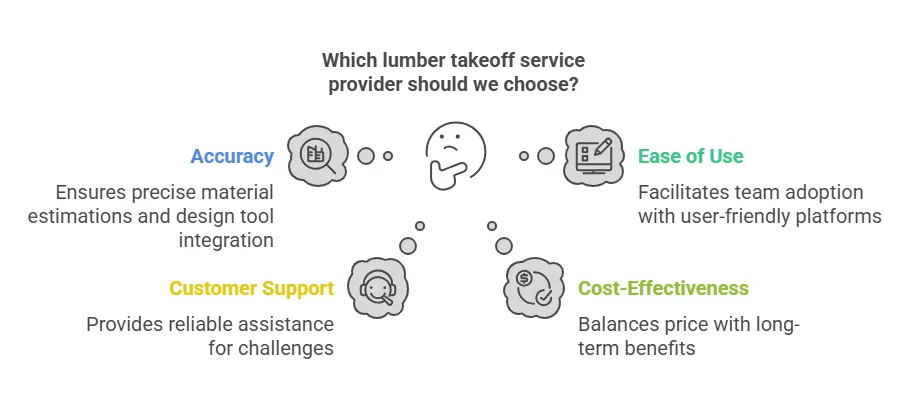

When selecting a lumber takeoff service provider, it’s essential to choose one that fits your specific project needs. Here are some factors to consider:

Throughout my career in the construction industry, this is not the first time I have seen the implications lumber takeoff services have on project planning. The technology they implement for material estimations is way more efficient than what was previously on offer; it is accurate, fast, and cost effective. Advanced technologies like BIM, CAD, and even AI guarantee that construction crews will remain on schedule, work as efficiently as possible, and avoid going over budget or missing deadlines.

Employing such technologies will be beneficial for the precision and planning of any building project. In the case of lumber takeoff services, those benefits come at every stage of the project, right from the planning phase to execution.

0 Comments