Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Estimating concrete costs for construction projects can be tricky, mainly when the project is located in areas with high-sulfate soils. High-sulfate soils can be problematic because the sulfate levels in the ground can degrade concrete over time. To ensure your project stays on budget and the structure remains durable, it’s crucial to understand how to estimate concrete costs in these challenging conditions properly. In this guide, I’ll walk you through everything you need to know to accurately estimate concrete costs for high-sulfate soil regions—based on years of experience working in these environments.

High-sulfate soils contain elevated levels of sulfates like gypsum, which can react with concrete components, causing significant damage over time. When sulfate-rich soil comes into contact with concrete, a chemical reaction occurs, leading to expansion, cracking, and structural failure. In some of the projects I’ve worked on in areas like Texas and California, dealing with high-sulfate soils was one of the first steps we had to address.

To put it simply, sulfate attacks concrete. Understanding how this works is crucial for choosing these regions’ correct concrete mix, materials, and building practices.

When sulfate interacts with concrete, it forms ettringite, a substance that expands as it forms, causing cracks and weakening the structure. This process not only compromises the durability of your concrete but can also shorten the lifespan of your foundation, driveways, and other concrete structures. I’ve seen firsthand how skipping this step—failing to test and adjust for sulfate—led to costly repairs in the long run.

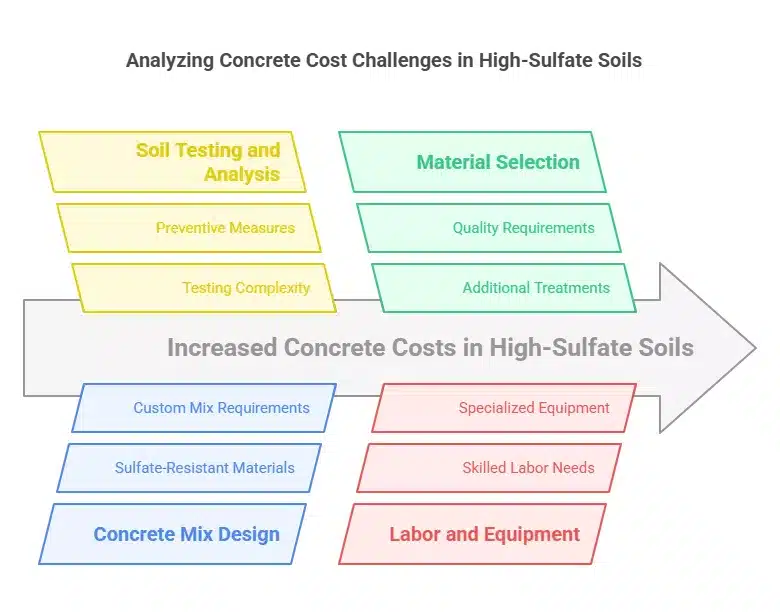

The unique challenges of high-sulfate soils lead to several factors that can significantly impact the cost of concrete. These include the need for specialized materials, custom mix designs, and extra labor and equipment.

The very first thing you need to do is test the soil. This step is crucial, as it will determine how much sulfate is present and whether any additional measures need to be taken to prevent damage to the concrete. From my experience working on these projects, I cannot stress enough how important this is. If you fail proper soil testing, you’re opening the door to potential structural failures.

The cost of a soil test typically ranges from $500 to $1,500, depending on its complexity. This cost might seem like an extra step, but it will save you from more expensive repairs.

Once you’ve completed soil testing, it’s time to select the right concrete mix. When dealing with high-sulfate soils, you need a sulfate-resistant concrete mix. Regular concrete may not stand up to the chemical reactions that happen in these environments. I remember a project in California where the mix initially used wasn’t resistant enough, resulting in cracking within just two years. The contractor had to redo the foundation, doubling the initial costs.

Unique concrete mixes can be more expensive than standard ones. To make the concrete resistant to sulfate, you’ll likely need to use:

While these materials can increase the cost by 10-20%, they’re essential for ensuring the longevity of the structure.

The choice of materials directly impacts the cost. Standard concrete doesn’t cut it in high-sulfate soil regions. Instead, you’ll need higher-quality cement and possibly additional treatments like:

These higher-quality materials ensure that the concrete can handle the sulfate attacks over time but can significantly increase your budget.

Because working with high-sulfate soils often requires unique materials and techniques, you might need to hire skilled labor. Specialized equipment to mix and pour the concrete could also add to the overall cost. In one project I worked on in Nevada, the skilled labor required for mixing and placing the sulfate-resistant concrete added about 15% to the overall labor costs. But it was worth the investment as it ensured the project didn’t face premature failure.

Transportation costs can add up if the construction site is in a remote or hard-to-reach area. This is especially true when working with specialized concrete mixes that may need to be delivered from specialized suppliers. In my experience, transport costs increased by 25% in projects far from the nearest concrete plant.

Estimating concrete costs in high-sulfate soil regions involves several steps, each affecting the final budget. Here’s how to approach it:

Before you start, perform a soil test to determine the sulfate content in the soil. This can help avoid expensive mistakes in the future.Depending on the complexity, expect to spend between $500 and $1,500 for the test.

After reviewing your soil test results, choose a concrete mix that is sulfate-resistant. Ensure you use sulfate-resistant cement and possibly include additives like fly ash or slag to minimize reactivity.

Factor in the additional costs for skilled labor, equipment, and machinery to work with specialized concrete. Labor can account for 10-20% more than in standard construction projects.

If you need additives or sealants for extra protection, ensure these are factored into your overall material costs. Depending on the region and the materials required, this could add another 5-15% to the budget.

Consider the distance to the nearest concrete supplier and any additional transportation costs for unique mixes or equipment.

To ensure the concrete lasts and your project stays on budget, follow these best practices:

Estimating concrete costs in high-sulfate soil regions requires special consideration, but with the right approach, it’s entirely possible to stay on budget while ensuring the durability of your project. By understanding the effects of sulfate, selecting the right materials, and factoring in all necessary costs—such as labor, testing, and transportation—you can protect your investment for years to come.

If you need help with Masonry Estimating Services to accurately calculate the cost of your project, consult a professional who specializes in concrete work for high-sulfate soil regions. Taking the extra steps today will save you money and headaches tomorrow.

0 Comments