Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

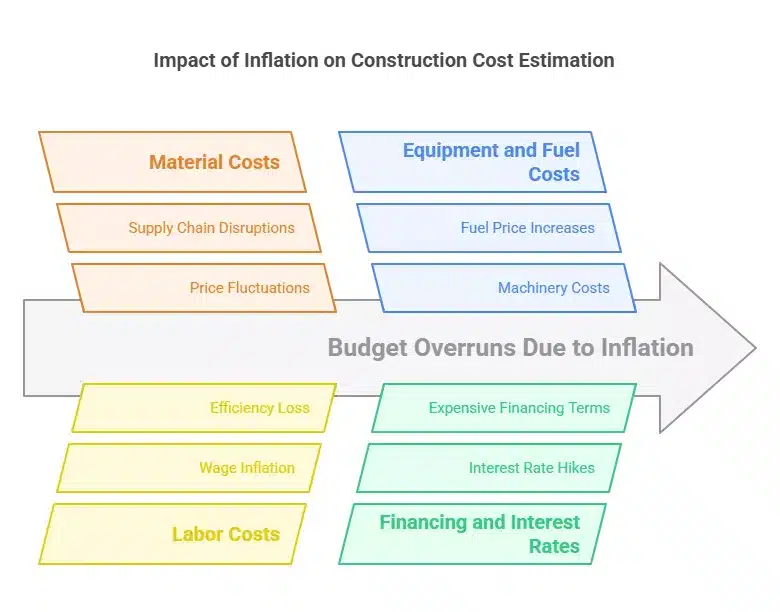

Inflation is an ever-present concern for the construction industry. As material costs rise, labor wages increase, and project timelines stretch, accurate construction cost estimation becomes even more critical. But how can construction professionals keep their projects within budget despite inflationary pressures? In this article, we’ll explore the various ways inflation affects construction costs and provide actionable strategies to manage cost estimation during inflationary periods.

Inflation refers to the general rise in prices across the economy, reducing the purchasing power of money. In construction, inflation can have significant effects, especially on the costs of materials, labor, and financing. If you’re not prepared, inflation can cause your project’s budget to spiral out of control.

Inflation can cause dramatic shifts in the prices of raw materials, such as lumber, steel, concrete, and other essential components. For example, in 2020, the price of lumber increased by over 300%, significantly affecting project budgets. As global supply chains are disrupted, prices for essential materials can fluctuate, leading to uncertainty.

Solution: To manage this, project managers should:

Wage inflation is another challenge, as workers demand higher pay to keep up with the cost of living. In 2021 alone, construction wages in the U.S. rose by 5.4%, which directly impacts project budgets.

Solution: To handle rising labor costs:

Inflation also impacts the costs of machinery, tools, and fuel. As fuel prices increase, machinery operation costs go up, affecting the overall cost of your project.

Solution:

When inflation rises, interest rates typically follow, making financing more expensive. This impacts loans for construction projects, increasing overall financing costs and the cost of capital.

Solution:

Inflation can be unpredictable, but with the right strategies, you can stay ahead. Here’s how to adjust your cost estimation process to minimize the impact inflation will have on your project:

Escalation clauses allow you to adjust the price of materials or labor if the cost rises beyond a specific percentage. These clauses protect both contractors and clients from unexpected price hikes. For example, if lumber prices rise by more than 10%, the escalation clause automatically adjusts the contract value to reflect the new prices.

Step-by-Step:

With inflation constantly shifting prices, using construction estimating software that tracks real-time material and labor costs is crucial. Tools like ProEst or Buildertrend allow you to stay updated on market prices, helping you adjust estimates quickly and reduce uncertainty.

Tip: Regularly check live cost feeds from your suppliers or estimate using historical trends adjusted for current inflation.

It’s always wise to set aside a contingency fund to cover inflationary cost overruns. Depending on your project, this could be anywhere from 5% to 15% of the total estimated cost.

Actionable Tip: Include this contingency in your early estimates and ensure stakeholders know it’s there to cover unexpected costs. This gives you flexibility without derailing the project.

Relying on one supplier can be risky when inflation impacts material costs. Diversifying suppliers helps mitigate price hikes from any single source.

Steps to Diversify:

Let’s take a real-world example: In 2021, a commercial construction project in New York faced unexpected price hikes due to material shortages and rising inflation. Initially, the project estimated $10 million in total costs. However, when lumber prices surged by 20% midway through the project, the project manager had to quickly adapt.

By using escalation clauses in contracts, the project manager increased the contract price by 5%, protecting both the contractor and client. Additionally, the team used ProEst software to track real-time lumber prices, allowing them to adjust the estimate promptly and prevent cost overruns. The project was completed on time and within budget, despite inflationary challenges.

As inflation continues to affect the construction industry, it’s essential to stay ahead of the curve. Anticipating cost changes and adjusting estimates regularly is more important than ever. By using smart strategies like escalation clauses, real-time data tools, and a flexible supply chain, construction professionals can navigate inflation without sacrificing project success.

Inflation presents a unique challenge for construction professionals, but with proactive planning and accurate construction cost estimation, you can minimize its impact. By understanding how inflation affects material costs, labor, and financing, and by employing strategies like escalation clauses and contingency funds, you can protect your project’s budget and ensure timely, successful completion.

0 Comments