Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Have you thought about how construction teams accurately record the materials required for a project? Traditionally, the process of material takeoff, or MTO, was lagging and highly inefficient, sometimes resulting in human error. But today, the soaring capabilities of technology have made MTO speedy, precise, and straightforward for teams engaged in construction projects. Whether through Building Information Modeling (or BIM, or automated software systems, technology is elevating the way construction teams estimate and calculate material costs.

This article seeks to illustrate the importance of material takeoff for modern construction projects while focusing on the changes brought about by contemporary technology.

Material takeoffs (MTO) refer to estimating the required amounts of material for a construction project. Be it concrete, steel, or even wiring, determining the right value helps in budgeting and planning. A project’s estimate accuracy is critical, as it heavily affects spend thresholds and timelines.

While working in construction, I soon discovered that material takeoff was a manual process involving blueprints, tedious hand calculations, and spreadsheets. Everything was in the blueprint at the office. The cost of missing even a single detail could skyrocket. It became evident over the years that there had to be a better approach.For a deeper dive into the basics, check out our detailed guide: What is a Material Takeoff.

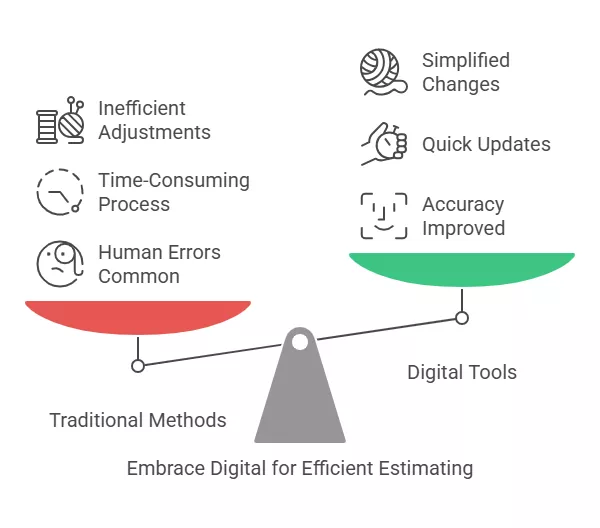

Prior to the advent of digital tools, material takeoff was conducted manually. Estimators reviewed blueprints and computed the quantities of materials required, oftentimes spending hours or days merely strategizing. Regrettably, the method was inefficient and could be erroneous.

Some of the issues we faced included:

After experiencing these challenges firsthand, I realized how important it was for the industry to adopt technology that could speed up and simplify this process.

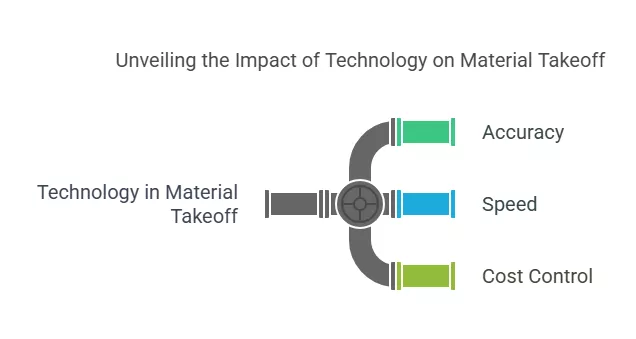

Currently, the situation is quite different. The implementation of tools such as Building Information Modeling (BIM), computerized takeoff software, and other tools provided in the cloud has enhanced the efficiency and accuracy of material takeoff. This is how it has changed:

BIM has changed the efficiency of material takeoff for the better. With BIM, it’s possible to design a three-dimensional model of a construction project; this model encompasses all the materials required for the project. It’s almost akin to possessing a virtual replica of the project that can be viewed from every perspective.

Here’s how it works:

From my experience, BIM has made it much easier to catch mistakes before they become a big issue, which ultimately saves time and money.

Gone are the days of manually counting materials on blueprints. Software like PlanSwift and Bluebeam Revu automatically pulls material quantities from digital plans. This makes the process much faster and error-free.

The benefits of using this software include:

I’ve seen this software in action, and it really does save hours of work, making it one of the most useful tools for any construction team.

As Procore and CoConstruct are cloud-based, construction teams can now share material takeoff data in real-time. This means that everyone on-site, in the office, or working remotely can access the most recent material information.

Here’s why this is important:

In my experience, having access to real-time data makes a huge difference in how smoothly a project runs, especially when you need to make last-minute adjustments.

When it comes to material takeoff, AI and ML technologies provide great help. They analyze data from previous similar projects and try to estimate the type and quantity of the required materials.

Here’s what AI and ML can do:

A report from the National Institute of Standards and Technology found that AI could improve material takeoff accuracy by up to 20%. That’s a big win for construction projects, and it’s an area that I’m excited to see develop further.

Here’s why I believe adopting these technologies is crucial:

For construction teams, using technology for material takeoff isn’t just a luxury—it’s essential for keeping projects on budget and on time.

As technology continues to improve, I expect even more advancements in material takeoff. Some of the exciting developments to look forward to include:

The future of material takeoff is digital, and I’m excited to see how new technology will continue to improve the construction process.

Construction teams and how they perform material takeoff have experienced the most groundbreaking change with the introduction of BIM, automated software, and cloud collaboration tools. These technologies offer speed, precision, and productivity. Personally, I believe these tools have helped significantly avoid mistakes, timeliness, and budget constraints.

If you are still stuck in the past with outdated techniques for material takeoff, you need to change your perspective. In this rapidly changing world, adopting new technology is essential to remaining relevant and punctually delivering high-standard projects.

0 Comments