Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Efficient resource allocation is regarded as the most difficult aspect of any industrial project. Whether it is a manufacturing facility, energy plant, or some other large-scale infrastructure project, procurement of materials, equipment, and labor at the right time is crucial to remain on budget and avoid delays. Material takeoffs assist in simplifying and streamlining most of these processes.

In this blog, we are going to talk about the specifics of material takeoffs, how they assist in resource management, and their significance in the completion of industrial projects. We are going to provide examples as well as give tips on using accurate material takeoffs to ensure that your project stays on schedule.

In simple terms, a material takeoff is figuring out all the materials required for a project which can be as extensive as concrete and steel to even electrical wires and piping. By checking the designs and blueprints of the projects, we are able to figure out exactly how much of each material is needed which aids in understanding the actual cost and material requirements of the project.

We have dealt with numerous projects in which material takeoffs were immensely helpful in maintaining everything organized at Axis Estimation. This answered budgeting concern as well simplifies the overall workflow.

Resource Management seeks to ensure that all materials, human resources and equipment are used in appropriate quantities and within the proper times. Having an accurate material takeoff, as described earlier, gives you skeletal estimates in terms of time and quantity of the required resources, subsequently allowing you granular control over equipment, personnel, and even temporal scheduling, resulting in a smooth execution devoid of friction moments.

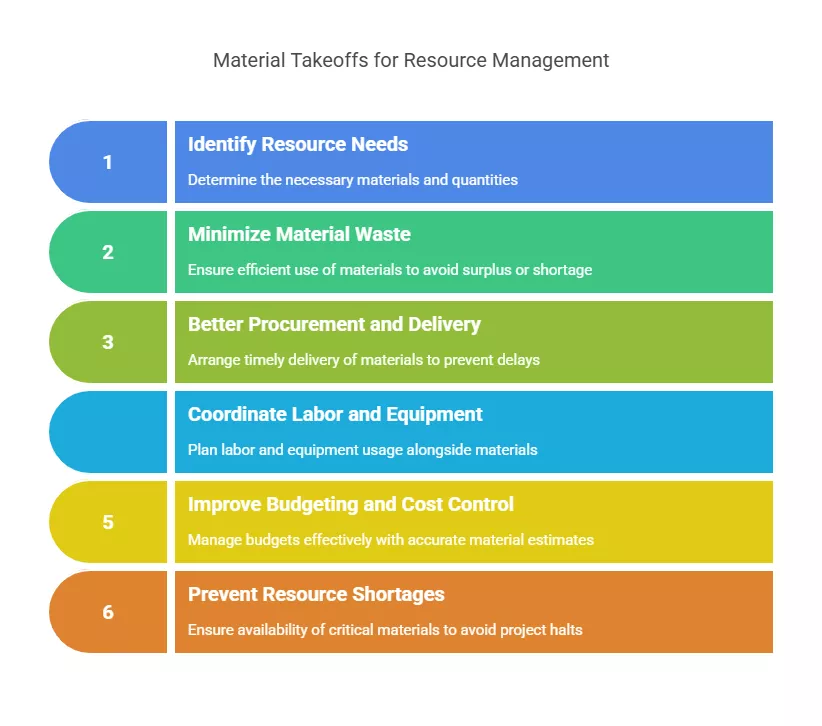

Here’s how material takeoffs help with resource management:

One of the biggest challenges in resource management is using materials inefficiently. Getting too much material leads to unwanted surpluses which occupy space but serve no purpose. On the other hand, getting too little will cause a delay due to waiting for supplemental materials to arrive.

Make sure that you order every required material in the appropriate quantity with the correct work order. We have witnessed how the correct execution of takeoffs ensures that waste is eliminated and materials do not accumulate which helps save money for clients.

When we have a material takeoff, all the orders can be pre placed by the procurement team, guaranteeing timely arrival of the materials. One issue we tend to face is project delays from late material deliveries. With precise material takeoffs, we can arrange the scheduling of material procurement and delivery before work commencement.

As an illustration, for a manufacturing facility we did a project recently and it was noted that accurate lists of skilled materials enabled the team to control delivery schedules for specific time hence delivery of materials right on time. Recovery from downtime was possible, providing the project with the ability to stay on schedule.

Takeoffs assist with planning labor and equipment alongside materials. With the right estimate, we can plan labor and equipment well in advance.

For instance, a readily available steel shipment means we need to have trained personnel as well as machinery on standby that can be conveniently accessed for immediate unloading and usage. Such an arrangement needs to be done ahead of time. All this facilitates seamless synchronization.

Exact material takeoffs are useful when trying to manage user budgets too. Forecasting costs becomes easier with the precise amount of materials needed. We handled multiple projects where our clients avoided unexpected losses due to project overrun, all because of efficient material takeoffs.

With an accurate material takeoff, you won’t need to rush for last-minute supplies and won’t underestimate how much material is actually needed. This leads to a cheaper and more reliable project.

The lack of resources may completely stop a project from moving forward. We have been involved in projects where material shortages caused major halts. With precise takeoffs, you have clear foresight of what needs to be procured which helps in planning so that critical materials are not unavailable during the project.

As an example, in one of the oil and gas projects we undertook, the material takeoffs gave us the opportunity to foresee certain supply chain complications. This enabled us to obtain the correct materials well in advance which ensured smooth progress of the project without any avoidable delays.

Supply chains are complicated. They need to ensure that raw materials are in the correct locations at specific times. The right information ensures that suppliers and financial planners are able to deliver. Takeoff lists aid in providing detailed lists of the materials to be sourced, enabling faster response for quotes from suppliers.

Less hassle is needed as there will not be a need for frantic last-minute aid. There is smooth flow with no inadequate material suppliers. Our team has dealt with numerous projects where our material management aided in removing last minute mad dashes fueled by inadequacy in resource planning.

On time pre-scheduled delivery of materials fulfills the provided deadline while helping artisans finish their tasks on schedule. Set project timelines can easily be broken. It can either lead to equipment not working or skilled workers left without work. Using accurate material takeoff methods (estimating total quantity of items needed to complete a construction project), material shifts can be synced with project timelines to guarantee labor and equipment will be accessible at appropriate times.

As for example this assists precise planning ahead avoiding meeting project deadlines late. Just look at this major construction firm we recently worked with, through our material takeoffs they adjusted their delivery shifts and avoided any delays. PEr careful planning there were no missed deadlines ensuring project parameters and timeframes always met seamlessly.

At Axis Estimation, we incorporate software such as BIM (Building Information Modeling) and estimating software Bluebeam, which improves the accuracy and speed of material takeoffs, while also simplifying their management. These tools assist in providing detailed takeoffs with better precision, thus saving time.

Without a doubt, technology has enhanced takeoff methods, and we always recommend the use of computers for achieving precision in estimating. For instance, using PlanSwift for digital takeoffs allows immediate updates towards changing materials thus preventing unnecessary delays in work progress.

Recently, we did a project for a chemical plant where precise material takeoffs helped save the project from catastrophic delays. The procurement issues stemmed from the initial project plan which did not outline detailed material estimates. The detailed material takeoff we provided allowed the procurement team to plan better and schedule materials without facing resource shortages. Consequently, the project was completed on time and under budget.

To sum up, material takeoffs are important for the efficient use of resources in an industrial project. They aid in precise procurement of materials which lessens waste, enhances budgeting, ensures delivery on schedule, and aids in timeliness. Accurate takeoffs are extremely helpful irrespective of whether you are at a construction site, a manufacturing plant, or any other industrial project.

Axis Estimation has got your back for any help needed to keep your industrial project in line. We provide accurate material takeoff services that assist in resource allocation and timely completion of the project within the set budget.

0 Comments