Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Before wood is ready to use in construction, furniture, or remodeling projects, it goes through a long and detailed preparation process. At Axis Estimation, we often help clients understand this process while offering our lumber takeoff services. Understanding the steps involved in lumber preparation helps you estimate better and avoid surprises during building.

Let’s walk you through each stage of the lumber preparation process, using easy words and real-life experience to explain it all.

The journey starts with choosing the right type of tree. Trees like pine, fir, cedar, and oak are cut based on what the wood will be used for. These trees are carefully selected and cut down using machines or chainsaws.

Quick Fact: Softwoods like pine are often used for house framing, while hardwoods like oak are used for furniture and flooring.

Once the trees are cut, the logs are loaded onto trucks and taken to a sawmill. Special equipment is used to avoid damaging the logs during transport.

Real-World Note: Damaged logs at this stage can lead to extra waste. We’ve seen projects where 10% of the delivered logs couldn’t be used.

At the sawmill, machines remove the bark from the logs. This step prepares the wood for cutting and removes dirt, insects, and other debris.

Tip from Us: Cleaner logs mean more accurate cuts and less waste—which helps with better lumber takeoff reports.

After cleaning, logs are cut into planks or boards using large saws. The way they are cut can affect strength, appearance, and cost.

Our Experience: Quarter-sawn lumber is often chosen for fancy projects like wooden staircases and trim work.

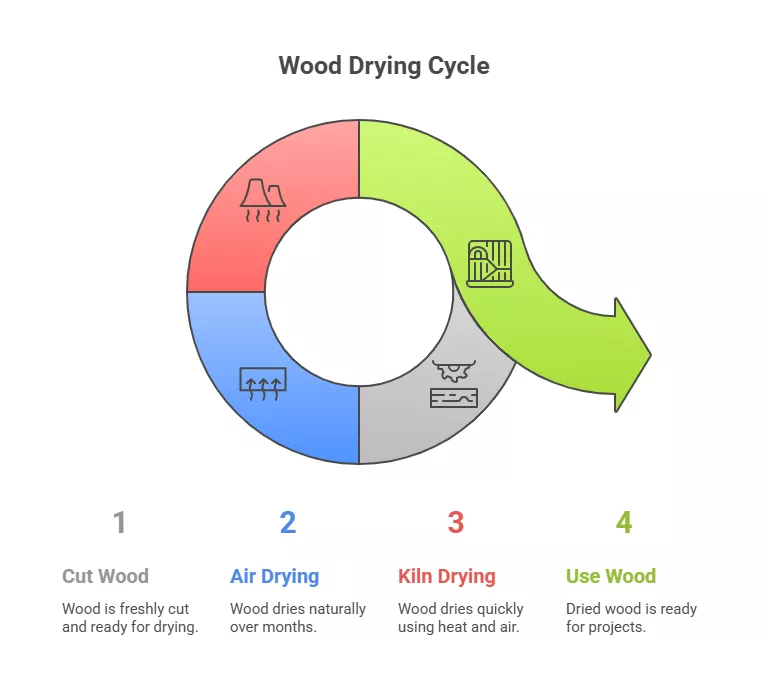

Freshly cut wood has a lot of moisture. It needs to dry before being used. Drying makes the wood stronger and stops it from shrinking or bending later.

Two common methods:

From Our Projects: We usually recommend kiln-dried lumber because it gives more consistent results.

Once dried, the wood is run through machines that smooth and shape it. This makes the wood easier to handle and gives it a uniform size.

Construction Tip: Planed wood is slightly smaller than rough-sawn wood. We include these adjustments in our lumber takeoff services to avoid mistakes.

The lumber is then checked and graded. This grading shows how strong and good-looking the wood is.

Real Example: We once worked on a house where all exposed beams had to be high-grade wood, which we carefully included in the estimate.

Some wood is treated with chemicals to protect it from bugs, mold, or rot. Treated wood is used outside or in wet areas like basements.

Helpful Tip: Always tell your estimator if you need treated lumber. It changes both the weight and cost.

👉 Learn how we handle treated vs. untreated wood in our lumber takeoff reports.

Once ready, lumber is bundled and delivered to job sites. It’s important to store the wood in a dry, flat place with good air flow.

On-Site Advice: We’ve seen delays when lumber was stored poorly and got damaged. Protecting it saves money and time.

Lumber preparation isn’t just about cutting trees. Each step helps make the wood safe, strong, and ready for building. By knowing this process, you can:

At Axis Estimation, we use this knowledge to offer accurate lumber takeoff services that help contractors, builders, and homeowners plan smarter.

Understanding how lumber is prepared before use helps you plan better, build stronger, and avoid waste. Each step matters—from cutting trees to grading and delivery.

If you’re planning a building project and want accurate material estimates, contact us at Axis Estimation. Our detailed lumber takeoff services can save you time, money, and effort.

Because wet wood can shrink, bend, or break over time. Drying makes it stable and strong.

Air-dried lumber takes longer and depends on weather. Kiln-dried lumber is faster and more consistent.

No. You need pressure-treated wood for decks, fences, and outdoor structures.

It’s a report that tells you how much lumber you’ll need for your project, based on your drawings or plans.

0 Comments