Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

Ranked #1 in Accurate and Reliable Estimation Services

A Fastest Turnaround 24 Hours!

In every construction, there are specific elements that are important in ensuring the entire building is stable, secure, and enduring. One of the main components is the lintel. Regardless of whether it is a home, commercial or for construction education purposes, knowing what a lintel is and why it is important helps someone to design and construct buildings that are much safer and enduring. Thus article will examine lintels in construction, their types, their materials, the installation process and details pertaining to their importance in the overall structural strength of buildings.

A lintel is a structural supporting beam that sits horizontally above windows, doors, or any other different types of openings in a wall, helping them support the weight above. These openings have their importance, for example, bricks require some gaps for air, light, and access, but these gaps also have disadvantages since the amount of material on the wall which is load bearing above the gaps is reduced. This is where the lintel comes in.

Spanning are placed to shifts the structure’s weight from above the frame to walls adjoining to the frame. They help prevent distributing damage such as windows and doors Structural damage, fracture or even collapse.

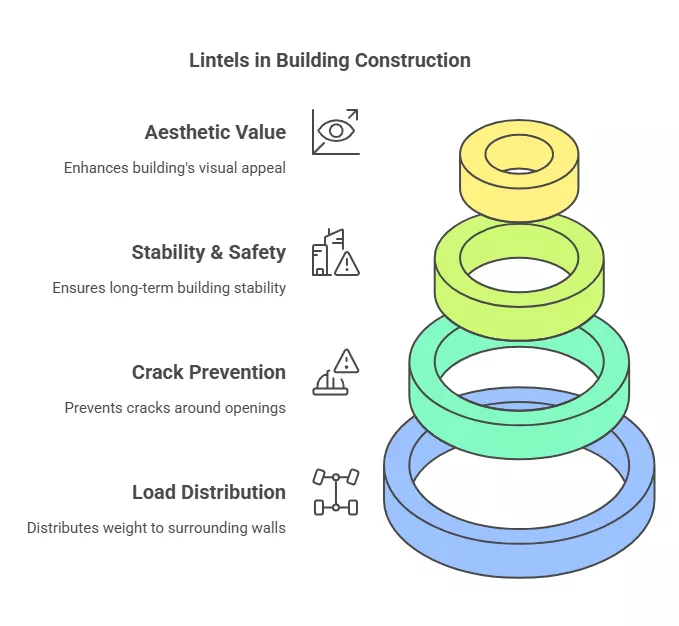

The importance of lintels in building construction cannot be overstated. They serve several crucial functions:

There are several types of lintels in construction, each designed for specific needs and building requirements. The choice of material and type depends on the size of the opening, the weight to be supported, and the overall design of the building. Here are the main types:

Reinforced concrete lintels are one of the most commonly used types in construction. These lintels are made of concrete mixed with steel reinforcement, which gives them added strength and durability. They are perfect for larger openings and heavier loads.

Steel lintels are often used when additional strength is needed, especially for larger openings. They are highly durable and resistant to corrosion, making them ideal for both residential and commercial buildings.

Wooden lintels are more commonly used in low-cost or smaller buildings. They are easy to install and can handle moderate loads. However, they are more susceptible to wear and tear, especially in areas with high moisture levels.

Stone lintels are a traditional option, used mainly in historic or masonry buildings. Stone provides an aesthetic appeal and has been used for centuries. However, stone lintels are heavy and require careful handling during installation.

Precast lintels are factory-made and then transported to the construction site. These lintels are cost-effective and efficient, especially in large-scale construction projects. They are easy to install and ensure consistent quality.

The material choice for lintels in construction depends on various factors like the load-bearing requirements, budget, and the overall design of the building. Let’s take a closer look at the most common materials:

Concrete is one of the most popular materials used for lintels because of its strength, durability, and versatility. Concrete lintels can be reinforced with steel bars to increase their strength, making them ideal for larger and heavier buildings.

Steel lintels are favored for their ability to support larger spans without the need for additional support. Steel is highly durable and resistant to damage from the elements, making it a preferred choice for commercial buildings and industrial spaces.

Wooden lintels are a cost-effective option for smaller buildings. They are easy to cut and shape, making them a flexible choice for simple construction projects. However, wood is vulnerable to decay, moisture, and pests, which can limit its longevity.

Stone lintels are often used for their aesthetic value and strength, especially in historic buildings or stone constructions. Stone is resistant to weathering and offers excellent load-bearing qualities, but it’s heavier and more difficult to install compared to other materials.

Installing a lintel is an important process that requires precision to ensure the stability and integrity of the entire structure. Here’s an overview of how lintels are typically installed:

Before installing a lintel, the construction team prepares the area where the lintel will sit, ensuring that the walls are clean and level.

The lintel is then placed in position above the opening. For concrete and steel lintels, this may involve using cranes or other machinery, especially for larger lintels.

The lintel is anchored securely, typically using mortar or steel supports. It must be perfectly aligned to avoid any shifting or instability.

Depending on the lintel type, it may require additional reinforcement. This could include adding more steel reinforcements or using a stronger mortar mixture to ensure that the lintel can withstand the weight of the building above.

Once installed, the lintel is carefully inspected for alignment and stability. Any issues found during this inspection must be addressed before proceeding with further construction.

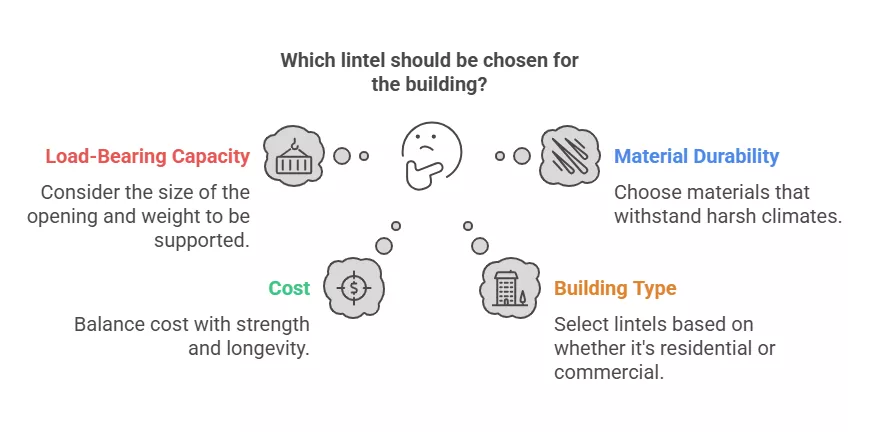

Choosing the right lintel depends on several factors, including:

The size of the opening and the weight that needs to be supported play a significant role in the type of lintel you choose. Larger openings or buildings with heavier loads require stronger lintels.

In areas where the climate is harsh, or the building will be exposed to the elements, more durable materials like steel or concrete may be necessary to avoid deterioration.

The cost of different types of lintels can vary significantly. Concrete and steel lintels tend to be more expensive than wood, but they provide better strength and longevity.

Whether you are building a residential home or a commercial building can also influence your choice of lintel. Commercial buildings often require more robust materials like steel or reinforced concrete due to the larger spans and higher loads.

While lintels are designed to last, they can face certain issues over time, such as:

Regular inspection and maintenance of lintels are essential to ensure the ongoing stability of the building.

Whether one is constructing a home or embarking on a larger commercial endeavor, understanding what a lintel is in building construction and its contribution towards structural integrity is crucial. For construction projects that require safety, stability, and longevity, the correct type of lintel must be chosen based on its material, load-bearing capacity, and cost.

If you’re currently working on a construction project and need expert help with planning and budgeting, consider reaching out to a construction estimation service. These services provide valuable insights into the costs of materials, including lintels, helping you make informed decisions for your building’s success.

0 Comments